TB Groupe’s collaborators turn the knives from Thiers into a success

Different procedures behind the fabrication of knives “Made in France”

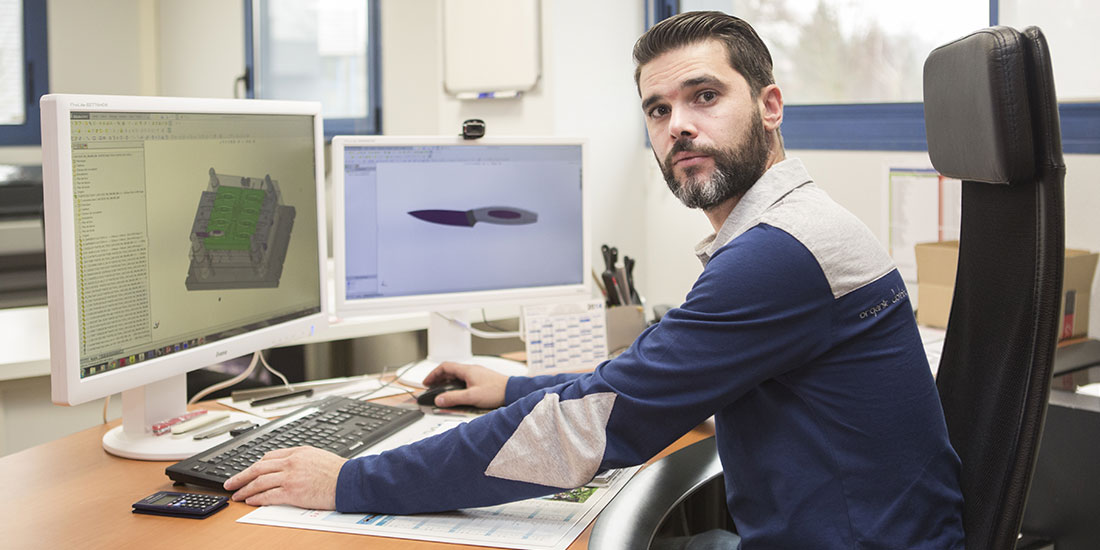

Located in Thiers the enterprise TB Groupe controls the entire process of manufacturing the knives produced in its workshops. The leader of cutlery, “Made in France,” collects teams of dynamic and dedicated individuals within its walls; these dedicated teams are what bring success to the knife industry located in Thiers.

The manufacturing sites which produce and design the knives as well as countless other products are all located in the city Thiers. The manufacturing process includes numerous manual procedures including meticulous polishing, assembling and calibrating of the knives which results in an exceptional cutlery product of outstanding quality.

TB Groupe’s strike force

The most important condition which has brought TB Groupe success is the shared passion that its collaborators bring to this demanding trade. All of Tarrerias-Bonjean’s collaborators are extremely involved in the organization and operation of the company.

Every echelon that makes up the TB Groupe enterprise shares their knowledge and their energy towards developing products of the utmost quality. Design, R&D and quality control departments, cutlery experts and logistic managers work in harmony in order to guarantee the organizational dependability of this cutlery enterprise based in Thiers. This collective effort keeps the standards for all of its operations high without cutting down on efficiency.

Different occupations supporting the excellence of cutlery “Made in France”

The organizational strength of Thiers’ cutlery

TB Groupe’s strength comes from its structured organization which leaves nothing to chance.

Each cog of the company has mastered a sector of knowledge. The organizational structure of the enterprise is composed of different gears whose attention to quality meshes to create this company’s outstanding efficiency.

Customer satisfaction is at the core of each production unit. TB Groupe’s collaborators work in the spirit of their innovative company philosophy, respecting the environment from the moment they purchase their raw materials until their finished product leaves the warehouse.

Diverse cutlery occupations

Today up to 150,000 articles can leave the Thiers’ workshops every day. All of TB Groupe’s products are created in three manufacturing sites which collectively span 16,000 m2 (approx. 170,000 ft2).

The different work sectors participating in the knife manufacturing process perform the following activities:

- Research and development

- Design

- Sales

- Production

- Quality control

- Logistics

TB Groupe’s marketing structure has been completely integrated into the company. The Design and Creation hub, which among other qualities has a desire to develop different models for innovative knives, was integrated into the company almost ten years ago.

Through their professionalism, the company’s production teams are constantly working to maintain TB Groupe’s standing. The process of handing down age-old knowledge and an affirmed taste for innovation is what makes this artisanal cutler the incontestable champion of cutlery “Made in France.”