TB Groupe invents the knife of the future

The renowned French manufactured knives

TB Groupe’s research department is the company’s central committee which is in charge of planning and manufacturing the knives on a medium-term basis. This department works non-stop on new projects and toward the creation of new blade and knife models.

This philosophy allows the entire enterprise to regularly advance and improve upon the design processes which create the diverse products developed by the group. The manufacturing techniques and protocols which are put into place are constantly being improved to promote high-quality production so that the company’s standing does not diminish. These French manufactured knives have a bright future ahead of them.

The EVERCUT® technology revolutionizes cutlery

For the past fifteen years TB Groupe’s Research and Development department has worked on developing new knife models. This French knife manufacturer works daily to create high-end products to maintain its reputation as one of the best knife manufacturers

The company’s system sets aside 5% of its total earnings for the Research and Development department. This has lead to major technological advancements in the history of both French and international cutlery. In 2010 when EVERCUT®, the innovative technological process which is used to create knives of the future, was launched the company was awarded with the Kitchen Innovation of the Year prize. EVERCUT® also won the European consumer’s award for 2011.

This technology notably allowed for the creation of a new line of revolutionary kitchen knives named Furtif, meaning stealth in French.

Innovation at the service of French manufactured knives

The spirit of perpetual improvement

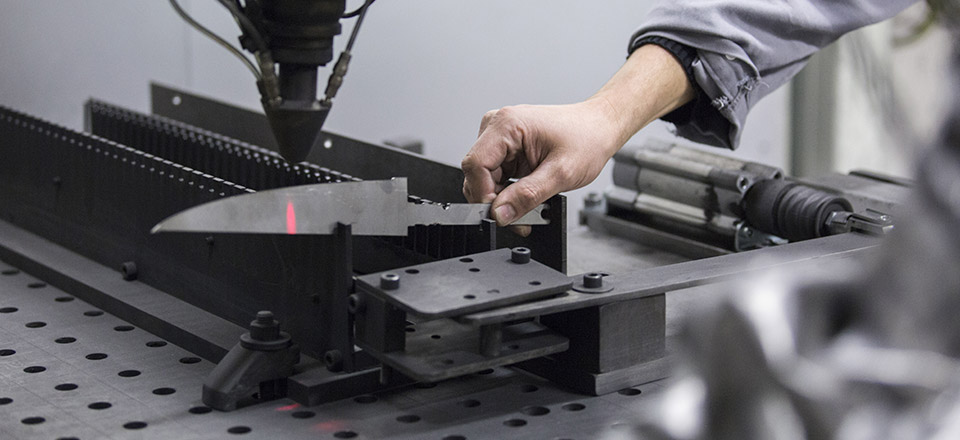

The group’s commitment to innovation and research allows the company to set their design ambitions high and allows all of their production units to improve upon their skills, which have already proven to be highly operational. Much attention is also given to maintaining and improving manufacturing tools.

The enterprise TB Groupe integrates all of the different aspects of the cutlery trade which have been modernized by industrial automation. This modernization gives the different units which compose the workshops both flexibility and the ability to react to different situations.The majority of the company’s manufacturing processes take place in France, affirming their "Made in France" brand image.

Innovation according to TB Groupe

A simple preliminary idea or a basic concept allows the enterprise to innovate and improve the company’s production. The Research and Development department’s investments as well as their mastery of every aspect of the cutlery business allows for the creation of 250 new “Made in France” manufacturing projects every year.

The large TB Groupe family is divided into departments who have considerable expertise. The departments are as follows:

- Research and development

- Design

- Sales

- Production

- Quality control

- Logistics